2022-05-24

Can You Cut LED Strips: Quick Guide

When we buy a strip light, it can be widely used in the dining room, living room, bedroom, and many other decoration applications that would be RGB color, cool white or warm white, and so on. Different colors, different color temperatures, and the lighting are different.

With the development of technology, we can not only use remote control but also use mobile phones to control the light belt. such as Forest Lighting led smart strips lights. In general, if the light strip has a cut line, it can be cut; if it has not, it is best not to cut.

LED strips are designed to be easy to cut apart with a pair of scissors. Each LED has a pair of copper dots at the end. As long as you cut between the dots, all of the LEDs will work.

From there, you can connect the LEDs to a power source either through a quick connector or by soldering. If they are connected correctly, all of the LEDs should light up in a colorful display.

Before cutting the light strip, please make sure that the strip you bought can be cut; otherwise, cutting the light strip may render it unable; at the same time, you must remember to disconnect the power; directly cutting a light strip that is connected to a power supply is extremely dangerous.

Measure the Right Length

Then the first thing you should do is to measure the right length, otherwise, too short or too long will cause waste. The LEDs come in 1 long strip. You can cut off individual LEDs when you need them, but they have to work properly. Determine how long your LED strip needs to be before cutting off any lights.

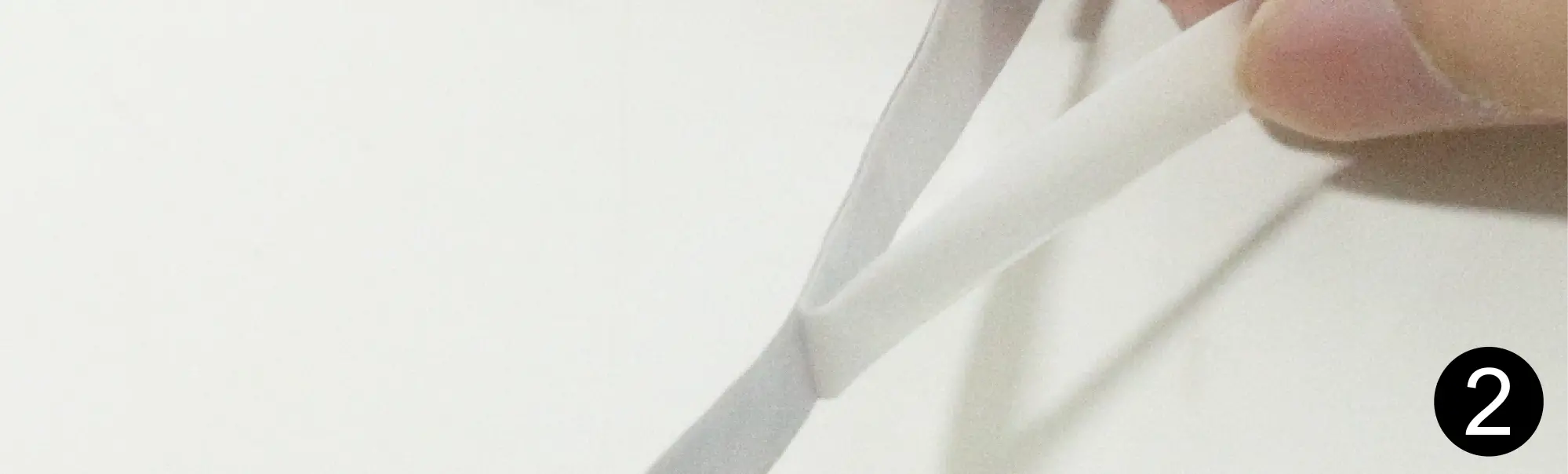

Cut the LED Strips

Secondly, look for the scissors logo on the light strip. Scissor logos have been placed on the cuttable part of LED light strips. To avoid causing damage, finding the scissor's logos before cutting is very necessary.

After making sure the length of light and scissor logo location, we can use our scissors and cut the excess strip. A pair of scissors will do the job. Please make sure you cut straight or you may cause the light to stop working.

Warm Tips

Or you can look for a pair of copper dots on the back of the LED strip. The copper dots indicate where each light connects to the next one on the strip. You will see a dotted cut line running between the copper dots. Choose the line closest to the LED length you measured earlier.

Please remember that the line is the only place you can safely cut the LEDs. If you cut anywhere else, some of the LEDs won’t work. Hold the lights still and cut along the dotted line.

You should be cutting between the copper dots. Line up the cut carefully to avoid damaging the LEDs.

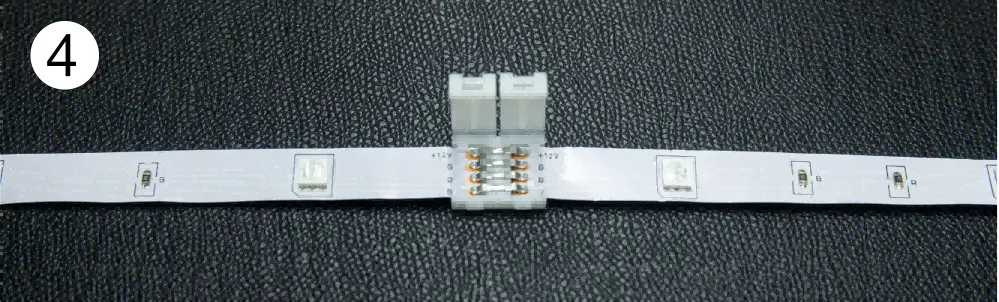

Fix the Pin

The next step is to fix the pin: Insert the pin completely in line with the copper wire, and pay attention to the insertion deviation of the pin

Insert glue around the circle of strip light connect cover. Install the front connector and connect the pin with the front connector. Install the end cap, inject glue into the four walls of the end cap and install it to the end of the strip light.

At last, install the fixed clip and lock the light belt with screws. Make sure that the fixed card is not stuck on the LED chip and resistance.

Check the Different Light Connection?

Ordinary Lamp Tape

After performing the above steps, if u find that the 12 volts or 24 volts LED light strip is still not lit, check that there is no connection issue. Be careful and always cut according to the logo on the strip, or the light strip may have been damaged during the cutting process.

COB Strip Lights

Please take particular care with the COB-led strip. The COB LED strip is a high-density product with numerous chips on the PCB. Therefore, it can be challenging to see the relationship between the voltage and the lamp beads for COB differentiated densities.

There are lots of led strips. The SMD, COB, and Addressable LED strips can be cut simply by clearly following the mouth of the scissor and cutting according to the line. There is no cause for worry as long as these LED strips are not cut off.

Neon LED Strip

However, the Neon LED strip is slightly different because of a thick silicone coating, which makes it necessary to locate the position of the scissors from the cutting window. It is not as obvious as the other LED strips but can be viewed through the clipping window.

The most common way for connecting LED strip lights is to weld iron. The welding method is to solder the two ends of the cut wire and then splice the two ends together. Make sure you plug your soldering iron into a power supply that allows for a temperature of 350 degrees Fahrenheit. Next, stick on a bit of solder, place the soldering iron on the splice for 1-2 seconds, and then remove the solder to cool.

Waterproof LED Strip

If you cut a waterproof LED strip, you will have to scrape off the glue at the position of the pad that will be welded after cutting the strip. Then you solder it after leaking the material off the pad.

It is very easy to cut a LED strip light. It just involves using a normal pair of scissors and cutting across the designated cut point. You just need to be careful not to cut outside of these cutting points.

Of course, If you have more problems, Pls contact us, we would provide customer service.

Enjoy cutting!

Solar Yard Lights: How it Works?

Light bulb Philippines suppliers – How to choose the right light bulb